Home Corporate Voices Bando Chemical Industries, Ltd. - Ashikaga Plant

| Company Name | Bando Chemical Industries, Ltd. - Ashikaga Plant |

|---|---|

| Address | 〒326-0832 188-6 Aragane District, Ashikaga City, Tochigi Prefecture |

| TEL | 0284-72-4121 |

| Website | http://www.bando.co.jp/english-1/en-nt3.html ¦Click to open a separate window |

Since founded, as a pioneer of rubber and plastic products manufacturer, Bando Chemical industries, Inc. is achieving a human and environment friendly "Monozukuri". We visited Ashikaga plant and interviewed with Minoru Aiba, Manager of Administration Group.

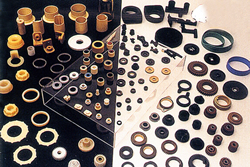

y High functional Resin Products z

y High functional Resin Products z

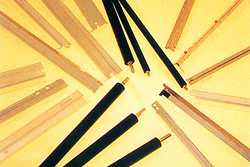

y Blade Roller for Optoelectronics z

y Blade Roller for Optoelectronics z

Bando Chemical Industries, Inc. has its head office in Kobe, and manufactures products categorized in power transmission belts, conveyor belts, optoelectronics parts, and industrial & chemical products.

Ashikaga plant produces power transmission belts, optoelectronics parts, and high functional resins. Each product are manufactured in the ratio of 40 % for power transmission belts, 40% for optoelectronics parts, and 20% for High functional resins.

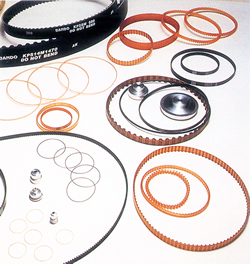

For the power transmission belts, at the time of this plant was developed, those bels for a friction transmission equipment, such as sewing machines, electric planers, are produced. Later, parts for stational videos and video cameras, are produced. Recently, we can see more demand for printers related parts such as carriage rollers, and paper feeder belts.

The optoelectronics parts are called blade-rollers. They are important parts for copy machines such as toner scraping blades, images developing blades, and image developing rollers. Those parts were transferred from Kobe plant which partially damaged by the great Kobe-Awaji-Large Earthquake in 1995.

For the chemical products, bearings and gears for electronics equipment, lately rings made of plastic materials in the replacement of metals, are produced.

All those parts produced in Ashikaga plant are made of urethane, except some plastic parts. The same type of belts made of rubber are produced in our Wakayama plant.

As for our production facilities, we have four plants domestically. in addition to Ashikaga and Wakayama plant, we have Kakogawa and Nankai plants. Kakogawa plant produces conveyor belts used in construction industries and foods industries.

Nankai plant produces automobile and industrial belts and chemical products.

For the products shipping routes, industrial parts are delivered to our distributors.

Almost all of our optoelectronics parts such as blades and rollers are directly shipped to manufacturers.

It is beneficial for us to directly communicate with customers, because we are able to hear customer's information directly in timely manners.

This plant was developed in 1973 , as our first plant in the Kanto area.

There were two reasons for selecting this location. First reason is this location is good for the production of urethane belts which have to be kept away from water.

Second reason is logistics. We wanted to proceed into the Kanto area because, at that time already, we had a large number of customers in there. By considering logistics also we selected here. Already completed Tohoku Expressway was also an advantage.

In logistics aspect, with recently opened Kitakanto Expressway, this is an excellent location.

Before the construction of this plant, all urethane products were produced in Kobe plant. After the completion of this plant, some parts production were transferred, and finally one year ago Kobe plant was closed and merged with this plant. At the time of plant merger, to get a merit of consolidated operation of our separated business units, the production line and employees of about 90 persons also were relocated to Ashikaga.

Our current total number of employees are about 450, and the most of them are local people. Our recruitments are made mainly for the local people also. Tochigi people work sincerely and are showing good performance on their works.

y Belts z

y Belts z

This is an exclusive plant for the urethane products in Bando Chemical Industries, Inc.

Urethane belts are superior in its cleanness and stopping accuracies. Especially it is very good for a clean-room environment, for example rubber belts are wear out in small pieces but urethane never does.

Also urethane belts are able to have clear gear teeth, it can be engaged firmly. The firm engagements mean less back-rushes and higher stopping accuracies.

Also environmental issues are taken into account. We do not use any harmful materials, which exhaust harmful when it's burned, for our belts. A reduction of energy consumptions is realized by reducing the load of the machine for easier rotations. This kind of considerations are made at during our development process.

Urethane or rubber has individual suitable applications, urethane belts which provides a cleanness or stopping accuracies and environmental friendliness, are our plant's unique point.

In Ashikaga, we have Research and Development Center also. We would like to inform that the most of our urethane products are born in Ashikaga.

We are participating on "Supporting model business for joint works connecting between villages and corporations" promoted by Tochigi Prefecture Rural development Section, and jointly performing a grass-cutting with the people in Sano City, Baien district. Actually it was started in March 2010, and been done for four or five times.

The purpose of this activity is to preserve natural environment by helping a grass-cutting of the agricultural roads in rural areas while enjoying nature.

In the other day, it was introduced by Shimotsuke Newspaper, and Tochigi TV too.

Also, we participate in volunteering activities such as cleaning of Watarase river and cleaning of the site of Ashikaga fire works event.

Also our baseball ground is opened and used to the local community people on Saturday and Sunday.

In addition, Ashikaga plant participate in eco-cap event. In 2009, total number of 14,000 caps, which equivalent with polio vaccine for 17.5 persons, were collected. We will continue this activities.

Further, cosponsorships with Tochigi[Eco-Mori-Fare and donations for disasters has been made. We are actively working on such activities.

Because our head office is in the Kansai area, we are not well-known by the people in Tochigi, and sometimes we shall wait our head office's decisions when we take some actions. In such case, we feel that we are not contributing enough for the local community. But we would like to let Ashikaga people know our company, and would like to work together more closely.

We promote CSR activities further, it would be appreciated if you could remember us when you heard the name of Bando Kagaku (Chemical industries).

Belts are not distinctive parts with covered inside machines, but it is a very important parts.

If you have a chance to see belt itself, some of our belts are marked with Bando logo, please watch it carefully. And it is grateful if you could notice that in such places Bando's products are used.